Multifab Manufacturing offers thermoforming capabilities from small to large sizes and thin to thick materials in pressure or vacuum forming. As experts in thermoforming, our engineers provide design for manufacturability services to match your requirements with our capabilities.

Why Thermoforming?

Thermoforming offers a competitive edge when manufacturing large parts and/or small volumes by offering a relatively low startup cost. The process can also produce parts thinner than what a traditional injection molding process can offer. Our pressure forming capabilities are the best in the industry and offer injection molding quality detail.

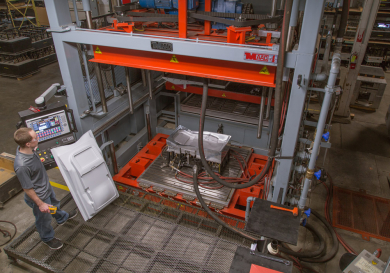

Multifab Manufacturing’s state of the art thermoforming equipment and process control delivers predicable and repeatable results. We get involved with customers early, helping steer the design to match our process capabilities even down to the detailing of the part drawings. This reduces start up time and ensures compliance.

Heavy-Gauge Thermoforming at Multifab Manufacturing

At the core of Multifab Manufacturing’s capabilities, heavy gauge thermoforming has shaped our entire company. With over 35 years of thermoforming experience it is the single most important process that we offer. We have learned that to be the best in the industry we must employ the best equipment, best tooling, and impeccable process control along with well-trained operators. We have also learned that pressure forming is a very under-utilized process in most industries. We would enjoy showing you how pressure forming can meet your needs at a fraction of the startup costs of injection molding.

Multifab Manufacturing has an ongoing strategy to reinvest in modern equipment that uses the latest systems. This plays into our analytical approach to process control by allowing us to track objective process parameters resulting in predicable outcomes. We also believe that there is no substitute for well designed and manufactured tooling. With quality tooling you will achieve a quality part. All of these elements are brought together when our continuously trained operators use our proven documented process to build our customers quality parts and deliver them on time.

Learn more about our Thermoforming Equipment.

Quality Seen the World Over

Multifab’s modern thermoforming equipment and advanced software and control capabilities enable us to maintain complete control over the process and the product.

These products are used worldwide in commercial, medical and aerospace applications that require the most demanding detail.

Learn more about thermoforming in Multifab’s Design Guidelines document.